In industrial environments—whether factories, warehouses, production floors or logistics hubs—the interplay between safety and efficiency is constant. Workers, machines, vehicles and materials all share the same space and rhythm. Even small blind spots, slow handoffs or hidden bottlenecks can lead to…

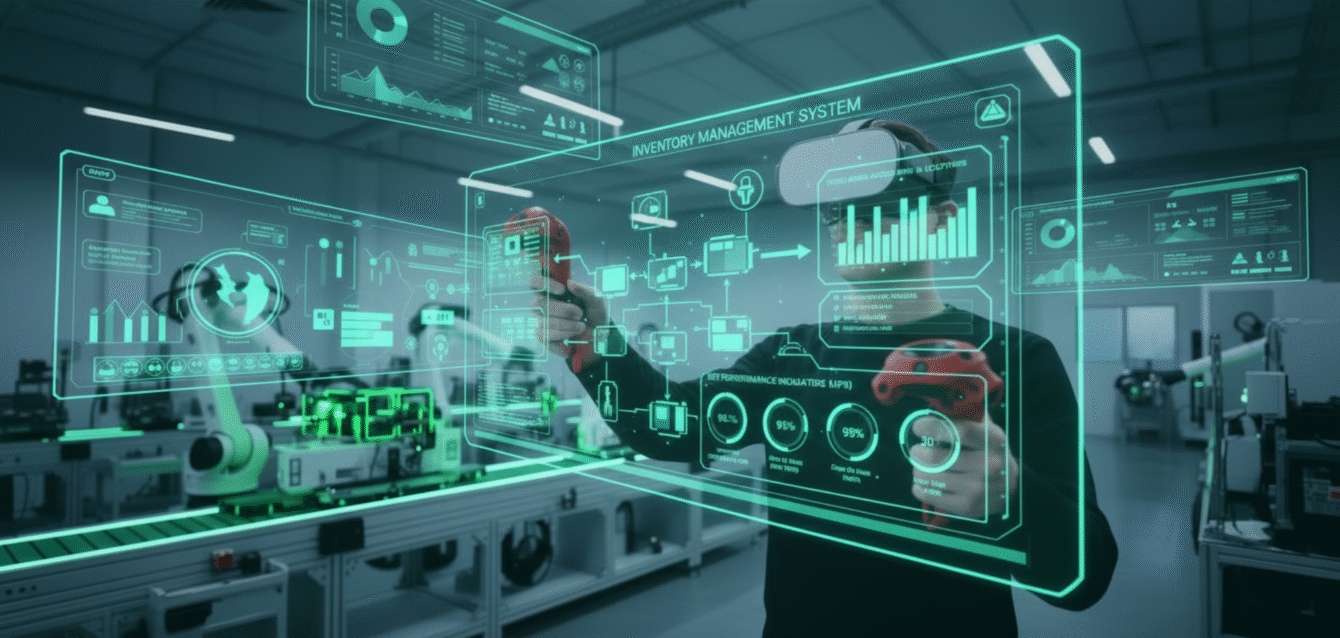

Predictive Analytics for Smarter Inventory Forecasting

In modern supply chains, the old adage holds: too much inventory ties up precious capital, while too little inventory risks lost sales, unhappy customers and production disruptions. Traditional forecasting methods—based on averages, fixed reorder points or instinct—no longer suffice in environments…

Automation in Warehousing: The Key to Seamless Inventory Flow

In today’s warehousing environment, where customer expectations accelerate and inventory volumes grow in complexity, manual processes simply can’t keep pace. Workflows that rely on manual picking lists, paper check‑ins, long walking routes, and fragmented systems create bottlenecks, errors, delays and hidden…

How Smart Inventory Management Minimizes Losses and Maximizes Efficiency

Inventory is the lifeline of any business that deals with physical products. Whether in manufacturing, retail, or distribution, managing stock correctly can make or break operational efficiency. Poor inventory practices not only lead to losses due to miscounts, theft, and expiry…

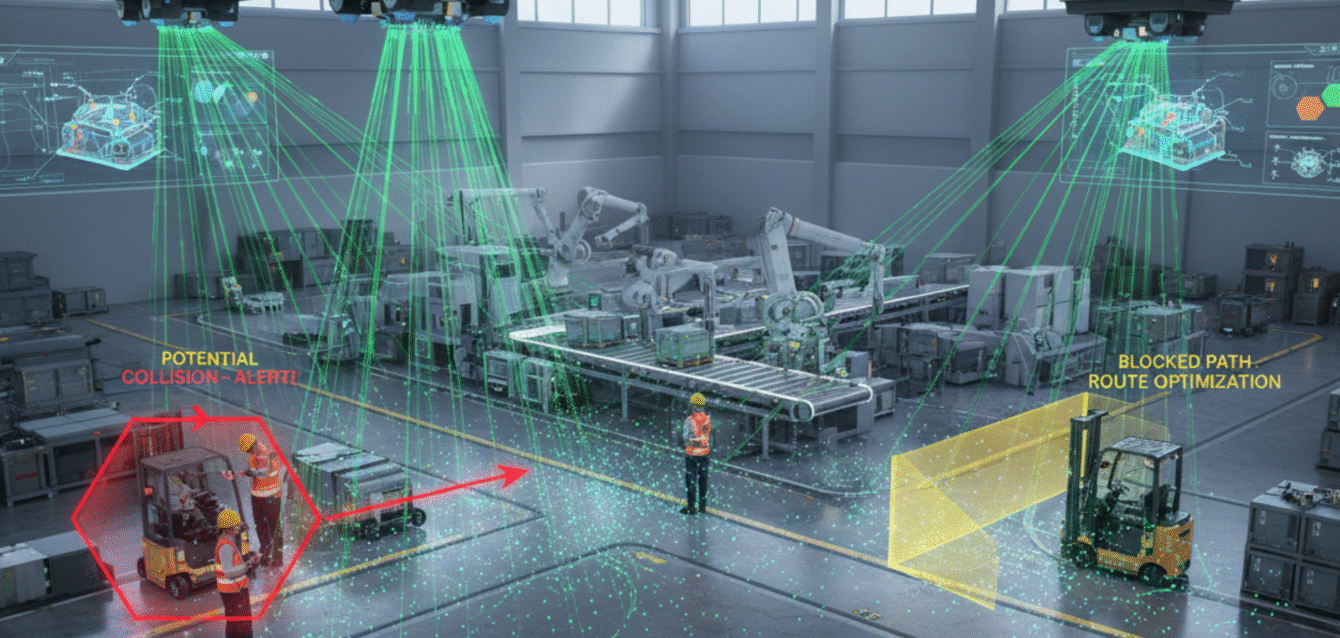

Reimagining Industrial Spaces with LiDAR-Based Spatial Intelligence

In expansive industrial settings—whether manufacturing halls, warehouses, logistics yards or multi‑level production zones—space is both a resource and a constraint. When layout, movement paths, storage zones, equipment placement and safety clearances are all managed with static drawings and manual measurements, inefficiencies…

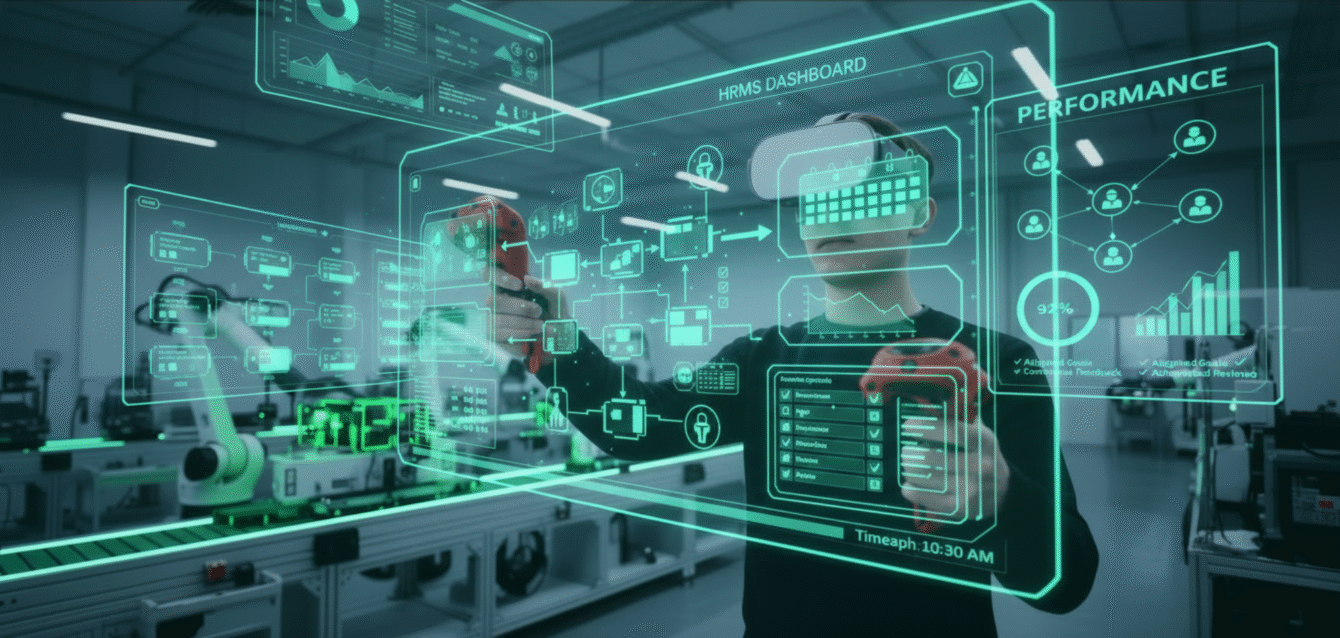

Streamlining Recruitment, Payroll, and Performance with Intelligent HR Systems

Recruitment, payroll, and performance management are at the heart of every organization’s human resource operations. Yet, in many workplaces, these essential functions operate in isolation, relying on disjointed systems and manual interventions that cause delays, errors, and frustration. Hiring a new…

Reducing Costs and Human Errors with Real-Time Inventory Visibility

In many businesses managing physical stock—whether finished goods, raw materials, or parts—the difference between profitability and loss often lies hidden in the inventory system. Manual counts, spreadsheets, disconnected databases, and delay‑laden reconciliations don’t just slow operations—they introduce human errors, mis‑matched records,…

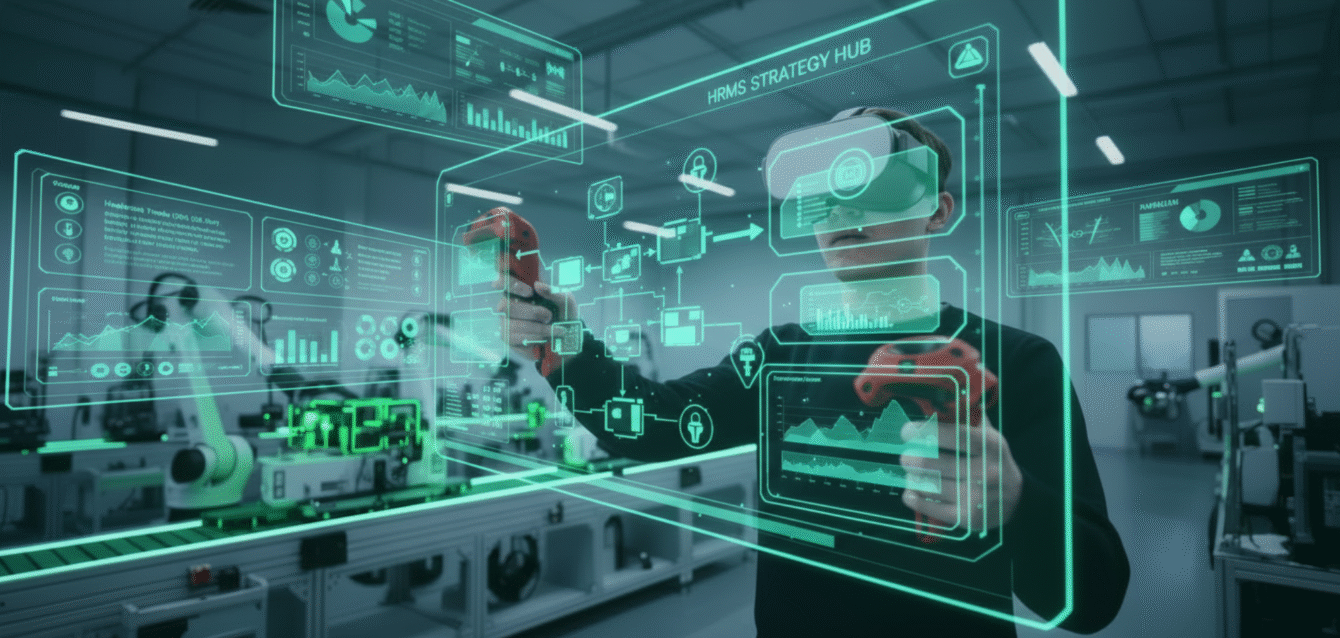

Building Data-Driven HR Strategies for Smarter Decision-Making

In a world where business decisions increasingly hinge on measurable outcomes, HR can no longer rely solely on instinct or outdated methods to manage people. Data is transforming how organizations think about their workforce—from hiring and retention to development and performance….