In high-stakes industries like manufacturing, healthcare, or logistics, compliance isn’t optional—it’s critical. And yet, preparing for audits is often a scramble: teams dig through outdated spreadsheets, scan paper logs, and send frantic emails to locate missing information. When data isn’t centralized…

Integration Without the Headache: ATLAS Pro + Your ERP

In today’s dynamic manufacturing and logistics landscape, aligning operational software with your ERP can feel like threading a needle. Most businesses juggle standalone tools for maintenance, inventory, assets, and operations, while the ERP sits separate—leading to double entries, broken handoffs, delayed…

Real-Time Supply Chain Visibility: Seeing Issues Before Customers Do

In an era where every hour of delay, every mismatch in documentation, and every unseen hand‑off in transport can ripple into lost revenue or damaged reputation, live tracking systems are no longer optional—they’re integral. Traditional supply chains often operate with blind…

From Chaos to Clarity: Managing the Asset Lifecycle with ATLAS Pro

In many factories and heavy equipment operations, assets such as tools, machines, jigs and instruments can quietly become sources of chaos. They’re purchased, moved, repaired, loaned out, lost, mis‑tagged, or forgotten. When assets aren’t tracked properly, you get unexpected downtime, lost…

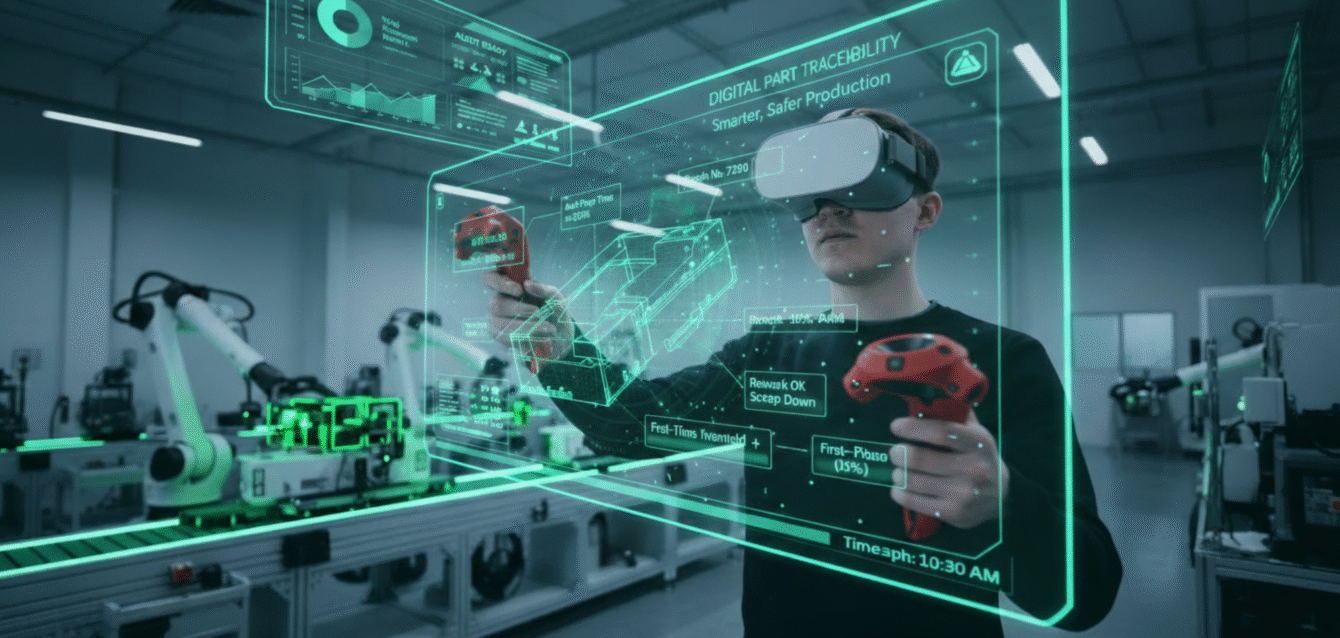

Why Digital Part Traceability Is the Key to Smarter, Safer Production

Manufacturing today faces rising expectations—faster delivery, tighter compliance, zero defects. But without the ability to track every part, process, and event, it’s easy for problems to slip through the cracks. That’s why digital part traceability has become a critical pillar of…

The Role of AI and IoT in Achieving Complete Traceability Across Supply Chains

In today’s global manufacturing and logistics environment, parts move through dozens of processes—raw materials to suppliers, shipments across continents, production lines, warehouses, carriers, and final delivery. The sheer complexity creates blind spots: delays that don’t get flagged, parts that stray off…

Reducing Downtime and Defects with Smart Part Tracking Solutions

Downtime and defects are two of the most stubborn challenges in manufacturing. While one brings production to a halt, the other chips away at quality, customer trust, and profitability. Most teams understand the consequences—but fewer have real-time tools that can prevent…

How Part Traceability Ensures Quality and Compliance in Modern Manufacturing

In the world of modern manufacturing, small mistakes can create big problems—whether it’s a single faulty component slipping through or a recall spiraling into thousands of wasted units. That’s why more factories are turning to digital part traceability systems that track…