In competitive markets where sales teams juggle ever‑higher quotas, complex buyer journeys and tighter margins, manual processes simply won’t cut it anymore. Reps waste valuable time on data entry, chasing approvals, logging follow‑ups and reconciling spreadsheets—tasks that don’t move the needle…

How EMRs Enhance Doctor–Patient Collaboration and Care Quality

In today’s healthcare setting, care is rarely delivered by a single doctor working in isolation—it involves teams, departments, diagnostics, follow‑ups and the patient themselves. Traditional paper‑based systems and disconnected records create barriers: consultations feel fragmented, patients retell histories, specialists wait for…

Smart Space Utilization: The Future of Industrial Infrastructure Planning

In large industrial facilities—factories, warehouses, logistics hubs or production campuses—the physical footprint often becomes a silent cost centre rather than a driver of productivity. When space is under‑utilised, layout is inefficient, storage is poorly organised and movement paths are convoluted, the…

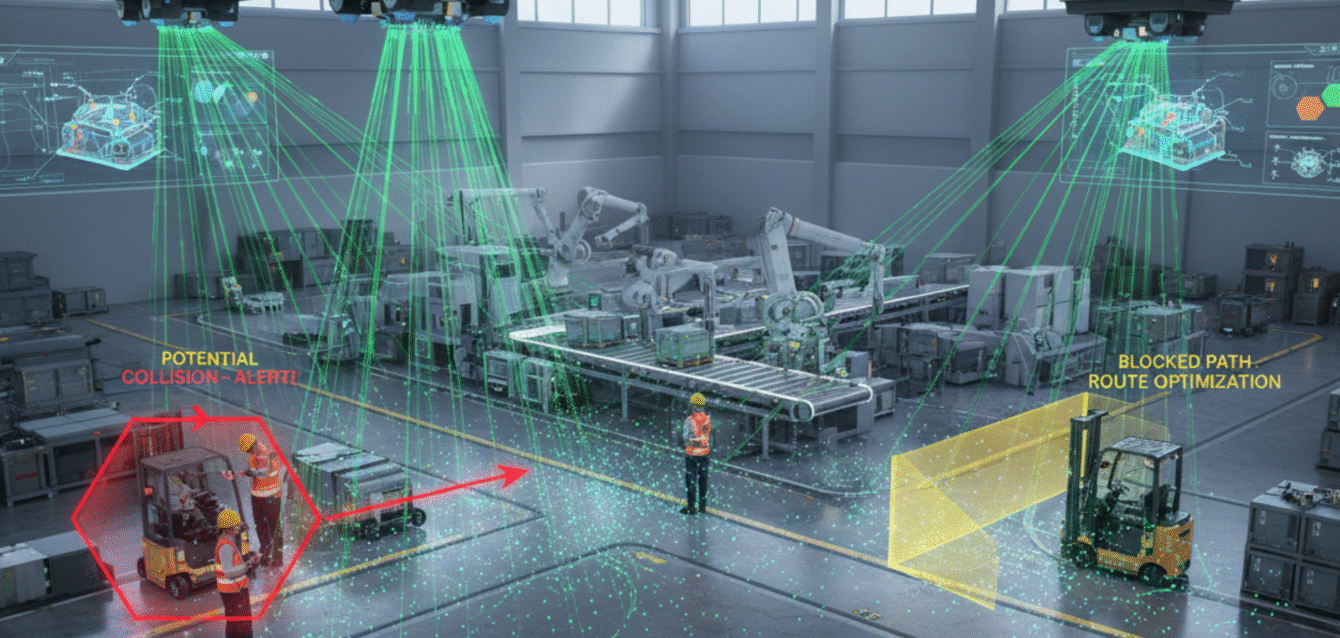

How LiDAR Improves Workplace Safety and Efficiency

In industrial environments—whether factories, warehouses, production floors or logistics hubs—the interplay between safety and efficiency is constant. Workers, machines, vehicles and materials all share the same space and rhythm. Even small blind spots, slow handoffs or hidden bottlenecks can lead to…

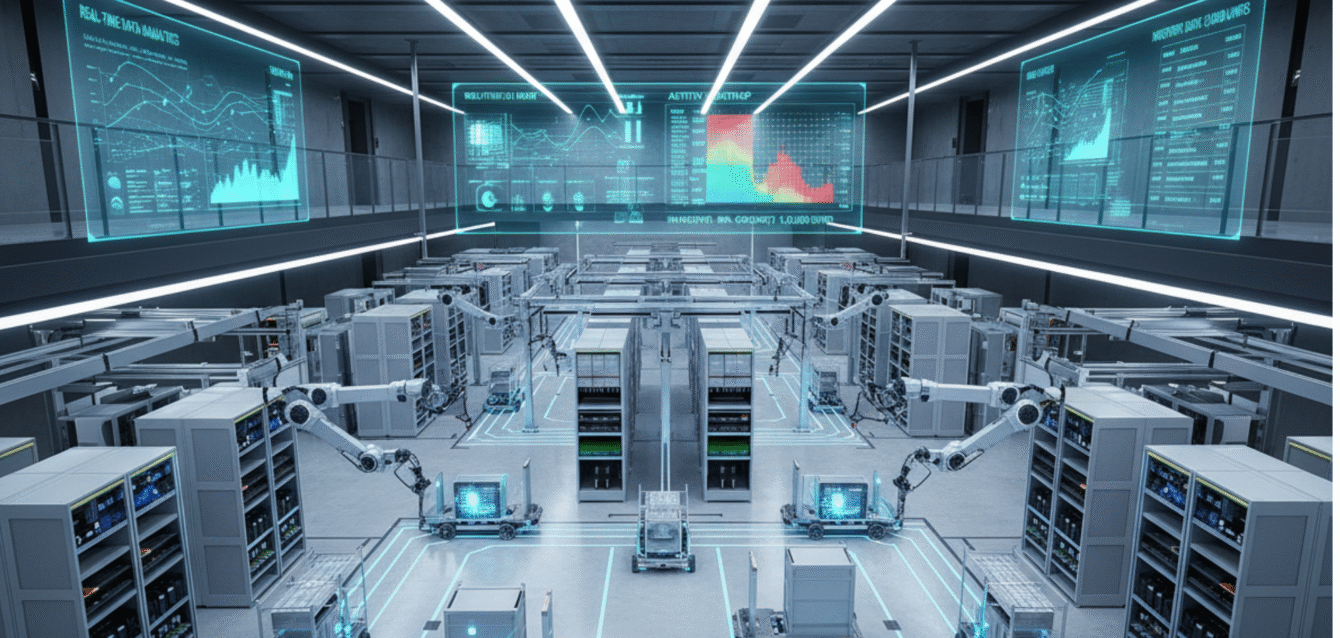

Automation in Warehousing: The Key to Seamless Inventory Flow

In today’s warehousing environment, where customer expectations accelerate and inventory volumes grow in complexity, manual processes simply can’t keep pace. Workflows that rely on manual picking lists, paper check‑ins, long walking routes, and fragmented systems create bottlenecks, errors, delays and hidden…

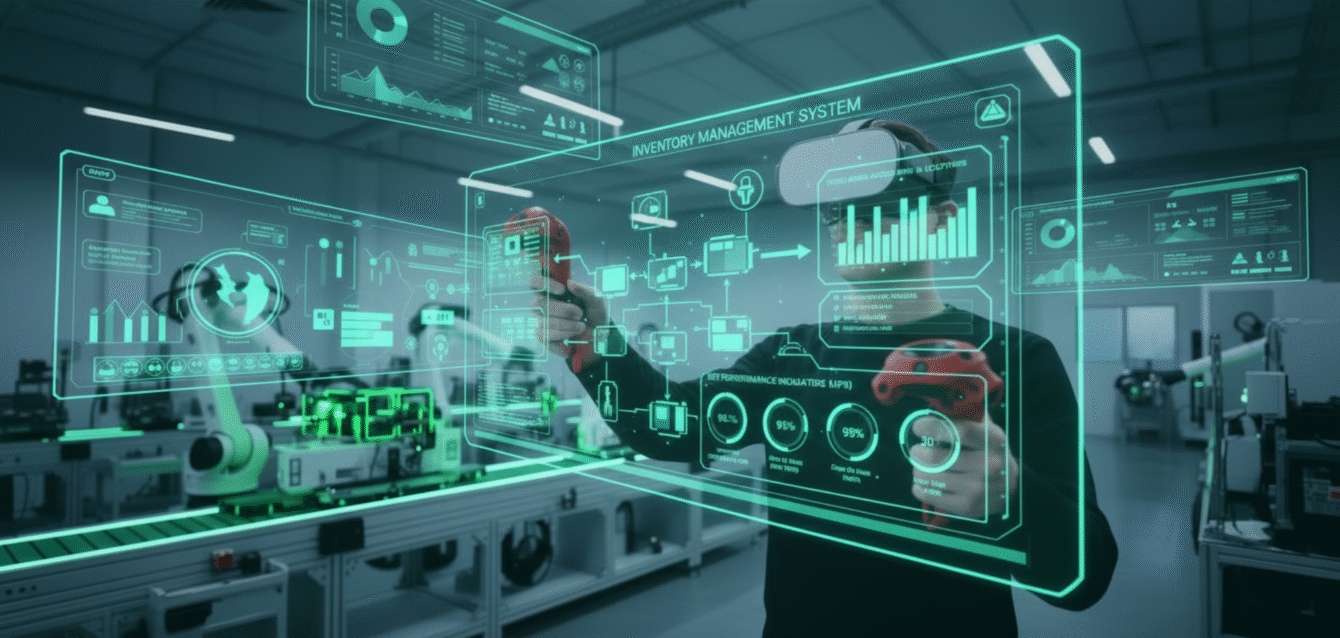

How Smart Inventory Management Minimizes Losses and Maximizes Efficiency

Inventory is the lifeline of any business that deals with physical products. Whether in manufacturing, retail, or distribution, managing stock correctly can make or break operational efficiency. Poor inventory practices not only lead to losses due to miscounts, theft, and expiry…

Reducing Costs and Human Errors with Real-Time Inventory Visibility

In many businesses managing physical stock—whether finished goods, raw materials, or parts—the difference between profitability and loss often lies hidden in the inventory system. Manual counts, spreadsheets, disconnected databases, and delay‑laden reconciliations don’t just slow operations—they introduce human errors, mis‑matched records,…

Reducing Downtime and Defects with Smart Part Tracking Solutions

Downtime and defects are two of the most stubborn challenges in manufacturing. While one brings production to a halt, the other chips away at quality, customer trust, and profitability. Most teams understand the consequences—but fewer have real-time tools that can prevent…