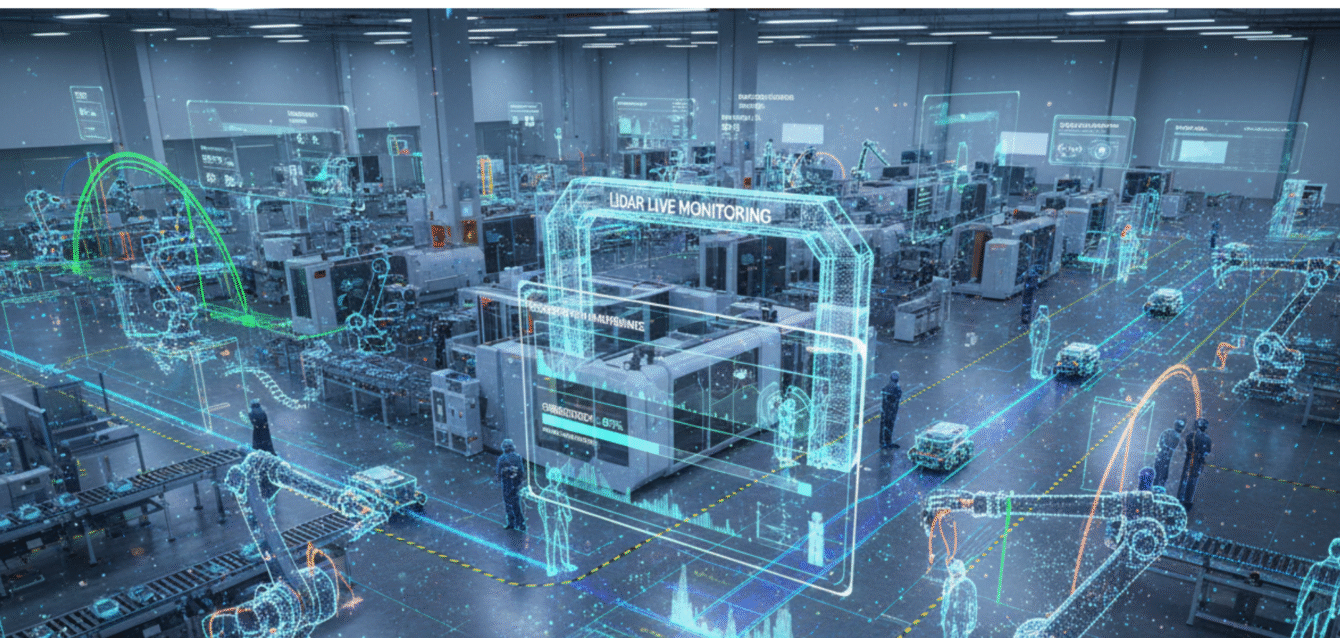

In the era of industrial transformation known as Fourth Industrial Revolution (Industry 4.0), physical assets, production flows and facility spaces are becoming digitised in ways that were previously unimaginable. What once began as discrete mapping efforts—scanning building shells, warehouse layouts or production halls—has evolved into continuous monitoring systems that feed live spatial intelligence into operations. With laser‑based LiDAR scanning, organisations can now generate dense 3D point clouds of their environments, overlay real‑time movement and change, and integrate this data into digital twins, asset‑management and workflow platforms. This transition from static mapping to real‑time monitoring is a critical shift: it turns passive models into active management tools, enabling predictive maintenance, dynamic routing, spatial optimisation, safety monitoring and much more.

As industrial ecosystems move from “measure once” to “sense continuously,” LiDAR technology becomes a foundation of the smart, connected enterprise.

The Evolution from One‑Time 3D Scans to Live Monitoring

For decades, factories, warehouses and production facilities used periodic 3D scans or manual surveys to capture as‑built geometry and layout information. These one‑off efforts provided a snapshot: rack positions, machine footprints, aisle widths, clearances and storage zones. While valuable, these static models quickly become outdated as operations change—equipment moves, materials accumulate, aisle widths shrink and layouts drift. LiDAR changed this game by producing dense point clouds rapidly and accurately. What began as mapping became the baseline for continuous monitoring. According to industry sources, LiDAR’s ability to provide high‑resolution spatial data is a key enabler for Industry 4.0 environments.

Today, the shift is towards live monitoring: sensors permanently mounted or mobile scanning systems capture changes in real time, detect drift, trigger alerts and feed dashboards. For example, a forklift route that narrows over time, unmapped staging zones creeping into aisles or storage densification that alters clearances—all become visible. By evolving from mapping to monitoring, organisations stop relying on outdated blueprints and start operating with live spatial truth.

How Spatial Intelligence Integrates with Digital Twins and Execution Systems

The power of LiDAR doesn’t end with generating 3D visuals—it lies in its integration with digital twins, operational systems and execution layers. A digital twin is a live mirror of the physical space, enriched with data on assets, people, flows and history. LiDAR point‑cloud data populates that twin with geometry and movement; then, sensors, analytics and execution systems overlay behaviour: asset movement, bottleneck build‑up, congestion, near‑misses, shift changes and routing. This creates a closed‑loop environment where physical actions update digital models, and digital triggers coordinate physical responses. Industry commentary identifies LiDAR as a cornerstone for enhanced situational awareness and smart manufacturing.

With this integration, facilities shift from static layout planning to live operations management. For example, when a layout change is planned, the digital twin can run simulations on traffic flow, forklift turns, aisle clearance and throughput—before any physical rearrangement. When monitoring is live, alerts can trigger preventive actions: move staging before congestion, adjust pathways when signals show wear or risk, or dynamically re‑route material flow to reduce collisions. This level of integration turns spatial intelligence into operational advantage.

Which Signals Matter Most for Monitoring Physical Space

When moving from mapping to monitoring, it’s critical to choose the right signals. LiDAR systems can detect numerous dimensions: occupancy (how many people or vehicles in a zone), movement paths (walking, forklift, AGV), static obstacles (pallets, equipment, spillage), changes in clearance (stack growth, encroachment), idle zones (under‑used space), and environmental drift (floor damage, floor settlement). Each of these, when monitored over time, becomes part of the spatial story of a facility. For instance, if a pallet stack grows near a beam causing clearance loss, it’s a risk not just of efficiency but of safety. LiDAR captures this.

The value lies in combining these signals with contextual data: shift start times, peak throughput hours, SKU turnover, vehicle traffic patterns and equipment usage. With that context, patterns emerge: certain lanes get congested every Thursday at 9 AM; staging areas encroach into aisles whenever a rush order arrives; forklift idle time spikes in a zone once a day. Monitoring these signals allows operational teams to spot trends, intervene before issues escalate, and align spatial operations with business rhythms rather than react to them.

Simple Yet High‑Impact Use Cases Where LiDAR Monitoring Saves Money

While the full vision of Industry 4.0 may feel distant, there are high‑impact, practical use cases where LiDAR‑based monitoring delivers value fast. These include:

Detecting aisle encroachment and reducing forklift travel time

Monitoring near‑miss zones and routing changes to reduce accidents

Tracking staging zone build‑up and avoiding hidden bottlenecks

Spotting dead or under‑utilised space for re‑allocation

Feeding data into demand‑driven slotting and storage decisions

What these use cases share is that they don’t require full factory automation to deliver return—they require spatial awareness, real‑time data, and operational responsiveness. For example, if monitoring shows a travel path that’s used twice as often as recorded, slotting high‑turn stock there can reduce travel distance. If a zone shows high occupancy of people and vehicles simultaneously, implementing a one‑way flow or virtual barrier can reduce risk and speed movement. These are smart moves enabled by the spatial map becoming live rather than static.

How Monitoring Supports Supplier, Stores and Line Connectivity

In the context of a supply chain or production line, spatial intelligence extends beyond internal zones: it connects supplier deliveries, inbound zones, storage, production, outbound staging and dispatch. LiDAR monitoring helps track inbound trucks, detect dwell time in receiving bays, visualize flow from stores to line, and highlight bottlenecks between storage and production zones. Because the spatial data is live, when a truck delays, staging builds up, or material flow slows, the system flags the deviation and triggers alerts or micro‑actions. This linkage of spatial monitoring with material flow breaks down silos between stores, production and logistics. As one article explains, LiDAR is increasingly part of smart manufacturing and logistics environments.

When spatial monitoring is integrated with stores and line operations, you gain synchronisation: you avoid parts sitting unused in buffer zones, reduce labour waiting for material, avoid shuttle‑truck queueing, prevent under‑utilised racks and ensure the right parts are available exactly where needed. This connectivity supports just‑in‑time flows, lean operations and resilient lines.

Ensuring Data Security, Roles and Multi‑Site Access in Live Monitoring

Live spatial monitoring introduces not just data capture but data governance: who sees what, how data is stored, how alerts are acted upon and how access is managed across multiple sites. When multiple teams and geographies access the spatial systems, role‑based permissions, audit logs, encryption and secure network connectivity become essential. For instance, a warehouse supervisor may see live congestion maps, while a regional manager views trends across sites over months. Effective monitoring systems support this layered access and provide logs of who accessed what, when and why. A review of industrial sensors notes the importance of secure, live data feeds within connected operations.

In multi‑site deployments, central dashboards aggregate spatial insights from each facility, highlight deviations, benchmark performance, and trigger corporate responses. Data security supports trust and compliance. Without it, spatial monitoring risks becoming a siloed system or a security liability. To realise the full benefit, monitoring must be not only live but trusted, integrated and governed.

Everyday Improvements You Can Expect in 60–90 Days

Deploying LiDAR spatial monitoring doesn’t require a decade — practical improvements often arrive within two to three months. As the sensor network starts capturing movement, bottleneck alerts, space changes and travel path data, operational teams begin acting: they move staging zones based on congestion, re‑route forklift paths, widen critical lanes, or reclaim under‑used space. These actions reduce travel distance, decrease equipment idle time, cut near‑miss incidents, and unlock capacity without capital expansion. Because the system shows real‑time cause and effect, teams adopt it faster.

Over this period you should see fewer downtime minutes caused by internal logistics, less labour spent searching for items, higher throughput per hour, fewer safety infractions or near‑misses, and improved utilisation of floor space. The transition from static layout to dynamic operations begins—and the facility starts feeling more responsive, streamlined and resilient.

The Takeaway

LiDAR‑based spatial monitoring is a foundational pillar of Industry 4.0—moving beyond mapping static layouts to real‑time, actionable intelligence that drives flow, safety, efficiency and agility. When physical space, movement, asset behaviour and changes are captured live and integrated into digital systems, industrial operations evolve. In a world of rapid change, spatial intelligence is not just a tool—it’s a dynamic capability that keeps the facility, and the business, ahead.