In industrial environments—whether factories, warehouses, production floors or logistics hubs—the interplay between safety and efficiency is constant. Workers, machines, vehicles and materials all share the same space and rhythm. Even small blind spots, slow handoffs or hidden bottlenecks can lead to near‑misses, accidents, damage or delays. Traditional systems—CCTV, manual patrols, static drawings—capture only part of the story and often lag behind the actual pace of change on the floor. Enter LiDAR‑based spatial intelligence: by using laser pulses to generate precise 3D point‑clouds and live mapping of people, vehicles and objects, organisations gain awareness of exactly what is happening, where and when. The result is safer workflows, fewer collisions, clearer paths and more productive movement.

In short, LiDAR bridges the gap between safety and flow—making workplaces not only safer but also more efficient.

Detecting Hazards Before They Happen with LiDAR

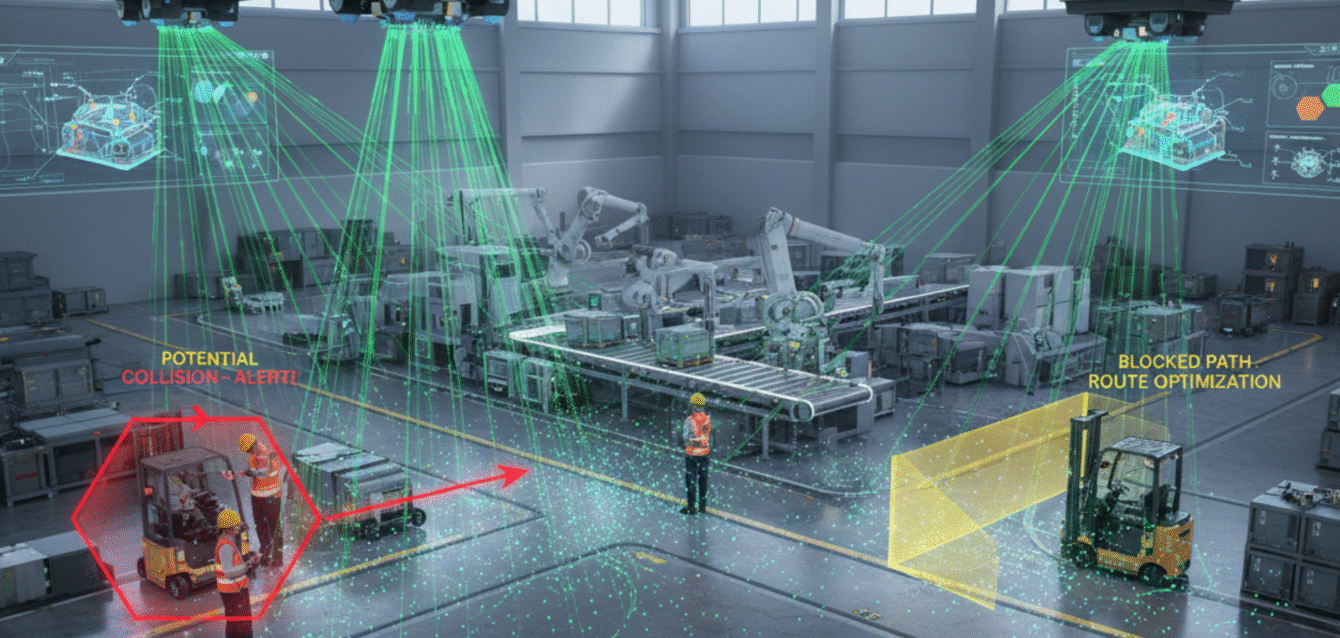

LiDAR technology excels in detecting subtle, dynamic changes in industrial environments that human operators or conventional cameras might miss. Whether it’s a forklift drifting into a pedestrian zone, a pallet creeping into a staging area, or an aisle becoming congested, LiDAR sensors pick up these deviations in real time. The system captures a 3D scan of the environment and updates continuously, enabling virtual safety zones, obstacle detection and path deviations to be flagged instantly. Research highlights that LiDAR‑driven monitoring provides a level of situational awareness previously unavailable in indoor industrial settings.

Beyond just detecting hazards, this capability enables proactive responses. When a safety zone breach is detected—or when vehicle traffic deviates from a predefined route—the alert triggers immediate action: reroute the vehicle, stop the instruction, notify a supervisor. In this way, near‑misses become events that are prevented, not just analysed post‑factum. The impact is both operational and cultural: workers feel safer, workflows run smoother and safety becomes part of the rhythm rather than an afterthought.

Enhancing Workflow Efficiency Through Spatial Awareness

In many industrial facilities, inefficiencies stem from constrained layouts, human/vehicle conflicts, ad‑hoc storage, and travelling distances that sap productivity. LiDAR‑based spatial intelligence delivers live maps of movement, occupancy, bottlenecks and congestion. By visualising where vehicles travel, where people walk, how material flows through zones—and how often paths are obstructed—the technology gives planners actionable insight into layout and workflow optimisation. For example, if LiDAR data shows persistent congestion at a fork in the aisle during shift change, rerouting or redesigning that path can reduce travel time and collisions.

This spatial insight doesn’t just yield incremental gains—it unlocks leaps in productivity. When vehicle and pedestrian paths are separated, staging areas are positioned according to movement patterns, and layouts are adapted based on real rather than assumed flows, material movement becomes smoother. Staff spend less time walking, waiting or negotiating congested zones, machines spend less idle time and overall throughput improves. Efficiency and safety rise together.

Integrating LiDAR into Vehicle and AGV Navigation

Automated Guided Vehicles (AGVs) and other automated material handling vehicles are increasingly common in modern industrial sites. Yet their safe operation depends on precise environmental awareness. LiDAR sensors enable AGVs to navigate dynamically, detect obstacles, adapt to changing layouts and avoid collisions—even in low‑light or cluttered environments where cameras or other sensors struggle. According to industry reports, LiDAR offers high resolution, simultaneous mapping and localisation (SLAM) which is especially valuable for intralogistics robots.

When LiDAR is integrated into AGV navigation, safety and efficiency both improve. Vehicles react faster, humans can safely share spaces, routes can be optimised and downtime due to misnavigation drops. The result is fleets that operate reliably, paths that are optimally used and industrial flow that accelerates—without compromising on worker safety or unexpected stoppages.

Monitoring People‑Machine Interactions and Near‑Misses

One of the key safety challenges in industrial spaces is the interaction between human workers and moving machines or vehicles. Traditional monitoring might rely on CCTV footage or post‑incident reports—but LiDAR enables real‑time zone monitoring, path tracking and near‑miss detection with far greater accuracy. Sensors create three‑dimensional zones around machines or vehicle routes and alert staff when proximity thresholds are breached or unexpected movement occurs. This proactive approach means behaviours or configurations that lead to risk can be corrected before accidents occur.

Beyond safety, this monitoring contributes to efficiency. Data on how often workers wait for vehicles, how often paths cross, where delays occur, or where machines idle can all be captured. With these insights, planners can redesign workflow, reschedule tasks or adjust machine assignment to reduce idle time and avoid conflicts. The dual benefit: fewer safety incidents and higher productivity.

Quick Wins Through LiDAR‑Enabled Alerts and Workflows

Deploying LiDAR doesn’t need to be a multi‑year overhaul to deliver value. Within weeks, teams can implement real‑time alerts, virtual danger zones, dynamic vehicle routing and congestion monitoring. For example:

Alerts when forklifts enter pedestrian zones

Notifications when staging areas encroach on travel lanes

Warnings when stacking heights exceed safe limits

These simple workflows create immediate safety and efficiency gains. Once alerts are live, patterns emerge, workflows adjust and safer behaviour becomes the default rather than a periodic audit. Over time these gains accumulate: fewer stoppages, fewer accidents, smoother flow and stronger operational confidence.

Scaling Safety Across Facilities With Spatial Intelligence

As industrial operations expand—with multiple floors, shifts, zones, automated systems and diverse workflows—keeping safety and efficiency consistent becomes harder. LiDAR spatial systems scale gracefully: each zone can be mapped, monitored and managed through the same platform. Whether it’s a mezzanine level, cross‑dock yard, automated racking zone or vehicle lane, the same laser scanning technology provides consistent awareness. As one report notes, LiDAR’s resistance to ambient light and its 3D perception make it ideal in settings where cameras fail.

This scalability also enables facility‑wide standardisation. Safety zones, vehicle/pedestrian separation, virtual audits and alert rules can be deployed across locations. With live dashboards and aggregated analytics, leadership can monitor near‑misses, travel delays, incident precursors and workflow bottlenecks. Safety, productivity and space utilisation can all be managed across the network—not just isolated zones.

Embedding LiDAR Into Industry 4.0 Workflows for Continuous Improvement

The journey doesn’t end once LiDAR is installed. True transformation comes when spatial data is integrated into your broader digital ecosystem: warehouse management systems, execution platforms, maintenance systems, dashboards, analytics engines and decision‑support tools. Live point‑cloud data can feed predictive maintenance, route optimisation, layout redesigns, accident investigation and performance dashboards. The closed‑loop cycle becomes: detect → alert → act → verify through scan. Over time, as spatial data accumulates, you build a digital twin of your environment that enables “what‑if” simulations, continuous flow optimisation and safety benchmarking.

When LiDAR becomes part of Industry 4.0 workflows, safety and efficiency are not just improved—they evolve. Instead of reactive correction, you move into proactive system design. Physical space, equipment, people and vehicles become part of a responsive, data‑driven system capable of adapting, optimising and predicting. In such environments, mistakes decrease, throughput rises, and operations stay ahead of disruption.

The Takeaway

LiDAR‑based spatial intelligence transforms industrial workspaces into safer, smarter environments. With real‑time hazard detection, workflow insights, vehicle‑human coordination, quick wins, scalable coverage and continuous improvement, organisations can both protect their teams and push their performance. Efficiency and safety don’t need to trade off—they can advance together.