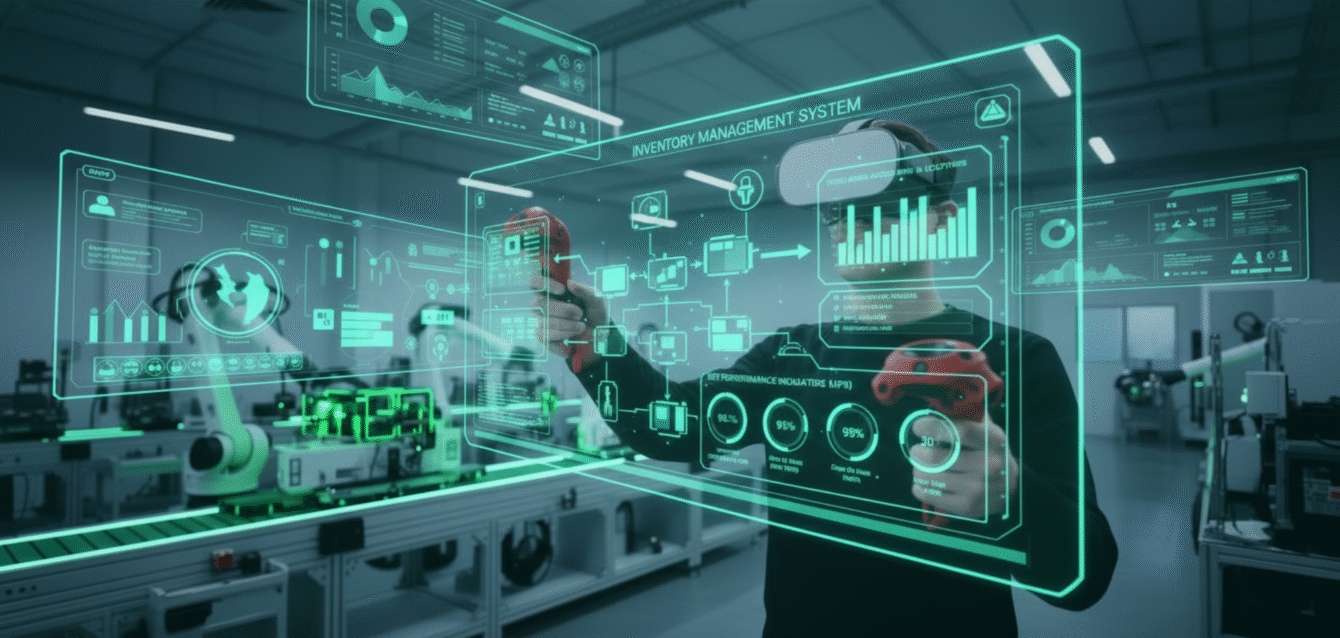

Inventory is the lifeline of any business that deals with physical products. Whether in manufacturing, retail, or distribution, managing stock correctly can make or break operational efficiency. Poor inventory practices not only lead to losses due to miscounts, theft, and expiry but also result in missed sales opportunities, customer dissatisfaction, and increased holding costs. Traditional inventory methods, often manual or fragmented across systems, are simply not equipped to handle the real-time demands of modern business. Smart inventory management tools are changing this by offering end-to-end visibility, predictive control, and automation that drive down losses while boosting overall productivity.

By transforming inventory into a dynamic, data-driven function, businesses can operate leaner, respond faster to demand shifts, and turn stock into strategic value.

Pinpointing Where Inventory Losses Begin

Losses in inventory are often hidden behind day-to-day chaos—misplaced items, inaccurate counts, expired goods, or unnoticed theft. These issues aren’t always due to negligence but are often the result of disconnected systems and manual tracking that fail to catch small errors before they grow. Smart inventory management tools change this by providing real-time tracking at each touchpoint. Whether through barcodes, RFID tags, or IoT devices, the system knows where each item is, its condition, how long it has been there, and who last handled it.

This kind of precision doesn’t just help trace losses; it helps prevent them. Alerts for aging stock, mismatched quantities, or unusual usage patterns give teams the power to act before the problem spreads. Managers can identify which areas or shifts see higher discrepancies, isolate process failures, and take targeted action. The result is a sharp drop in unexplained shrinkage and a significant improvement in accountability across the board.

Understanding Stock Movement Through Unified Visibility

Knowing what you have isn’t enough—you need to know how fast it’s moving, where it’s going, and how it’s being used. Many teams operate with siloed systems: purchase teams track incoming goods, warehouse staff manage bin locations, and sales teams monitor orders. Without a unified view, it’s difficult to assess which stock is slow-moving, overstocked, or nearing obsolescence. A smart inventory system consolidates this data, creating a central hub where every movement is visible in context.

When fast- and slow-moving stock are easily identified, businesses can make smarter decisions. Overstocked items can be bundled or discounted, slow sellers can be rotated or liquidated, and high-demand products can be reordered with precision. This not only reduces excess holding costs but also ensures capital is invested in inventory that actually delivers returns. Over time, inventory turnover improves and working capital is freed for more strategic initiatives.

Streamlining Checks That Catch Issues Early

Routine checks are a cornerstone of strong inventory control, but manual methods often miss subtle signs of trouble. Smart inventory systems integrate automated checks into daily workflows—ensuring that data is continuously verified without adding manual steps. Features like automated cycle counts, reorder threshold alerts, and expiry notifications enable teams to catch issues before they become financial hits.

The impact of these automated checks can be seen almost immediately. Shrinkage begins to decline, stockouts become rare, and emergency orders are significantly reduced. Teams no longer rely on spreadsheets or whiteboards to flag issues; they get real-time, system-generated insights that are easy to act upon. Over time, inventory control becomes proactive rather than reactive, saving both time and money.

Balancing Storage, Labor, and Inventory Flow

Efficiency in inventory isn’t just about the stock—it’s about how well it moves through space and systems. Poor layout, congested aisles, and inefficient workflows can add hours of labor and delay fulfillment. Smart inventory tools help map movement across zones, detect bottlenecks, and balance labor deployment based on real-time data. The goal is not just to store more—but to store smarter.

With data-driven layouts and labor optimization, businesses can assign high-turnover products closer to dispatch areas, cluster similar items together, and reduce walking time for staff. Labor is scheduled more efficiently, and storage space is used more intelligently. The result is a faster, more responsive warehouse that reduces fatigue, boosts morale, and delivers orders more quickly to customers.

Metrics That Reveal Inventory Health

When measuring inventory performance, many businesses look at outdated or incomplete metrics. Smart inventory systems offer a full suite of KPIs that tell a richer story about efficiency, accuracy, and responsiveness.

Key metrics to watch include:

Inventory accuracy (system vs. physical count variance)

Inventory turnover rate

Order cycle time (from request to fulfillment)

Holding cost per unit

Rate of returns or damaged goods

Tracking these KPIs over time not only highlights problem areas but also celebrates improvements. It allows leadership to tie inventory performance to financial outcomes, and supports more informed planning across operations, procurement, and finance.

Saving Costs Without Sacrificing Readiness

One of the biggest advantages of smart inventory systems is their ability to minimize holding costs without compromising availability. Predictive analytics based on demand trends, supplier performance, and lead times allow systems to suggest buffer stock levels that are safe but not excessive. This just-in-time mindset is tempered by real-time alerts, so teams stay ahead of disruptions without overstocking.

In practice, this means fewer rushed orders, reduced wastage, and lower insurance or storage costs. It also builds a culture of inventory discipline—where purchasing decisions are driven by data, not guesswork. The business becomes more agile, more capital-efficient, and better prepared for demand swings.

Short-Term Wins That Build Long-Term Capability

While long-term gains from smart inventory systems are substantial, the early wins are what often drive buy-in across teams. Within the first two to three months, businesses typically report cleaner records, faster fulfillment cycles, and fewer stock discrepancies. These quick wins validate the system’s value and open the door for deeper optimization.

More importantly, they show that smarter inventory isn’t just a back-office function—it’s a business enabler. From sales and procurement to finance and fulfillment, every team benefits when inventory becomes more predictable and transparent. This cross-functional impact builds momentum and paves the way for digital transformation across the supply chain.

The Takeaway

Smart inventory management is not just about tracking items—it’s about transforming operations. By integrating systems, automating checks, visualizing movement, and aligning decisions with data, organizations can reduce losses, increase agility, and unlock efficiency at scale. The sooner inventory becomes intelligent, the faster the business becomes resilient, responsive, and ready for growth.