In large industrial facilities—factories, warehouses, logistics hubs or production campuses—the physical footprint often becomes a silent cost centre rather than a driver of productivity. When space is under‑utilised, layout is inefficient, storage is poorly organised and movement paths are convoluted, the result is wasted cubic metres, increased labour travel time, higher energy use and slower throughput. Traditional planning methods rely on static drawings, manual audits and estimated occupancy: in short, guesswork. The future demands more than guesswork: it demands smart space utilisation. By leveraging sensors, spatial analytics, real‑time occupancy data and flow modelling, operations teams can transform infrastructure planning from reactive adjustments to proactive design. With visibility into how every square metre is used, when it’s used, by whom and for how long, planners can optimise layouts, allocate resources smarter, reduce waste and enable scalability, even in the face of changing demand.

Smart space utilisation turns “lots of space” into “effective space”—aligning capacity, cost and performance.

The Hidden Costs of Poor Space Utilisation

Even when a facility appears spacious, the real cost of poorly utilised space is often hidden. Idle racks, wide aisles that serve rarely moved stock, excess buffer zones, and staging areas creeping into travel paths all add cost without visible benefit. When space is over‑allocated it ties up working capital, increases energy and maintenance cost per square metre, and forces longer travel distances for staff and equipment. Conversely, under‑utilised zones may sit idle while other areas become congested, creating bottlenecks or requiring expansion prematurely. In industrial infrastructure planning, these inefficiencies compound: longer lead times, higher labour costs, slower change‑over, and less agility to scale operations.

By shifting to smart space utilisation, teams can begin to identify where space is wasted, where layout is misaligned with flow, and how space can be repurposed. This transitions infrastructure planning from measuring square footage to measuring flow‑through, from counting racks to counting movement and from static zoning to dynamic allocation.

Real‑Time Data and Analytics: The Foundation of Smart Utilisation

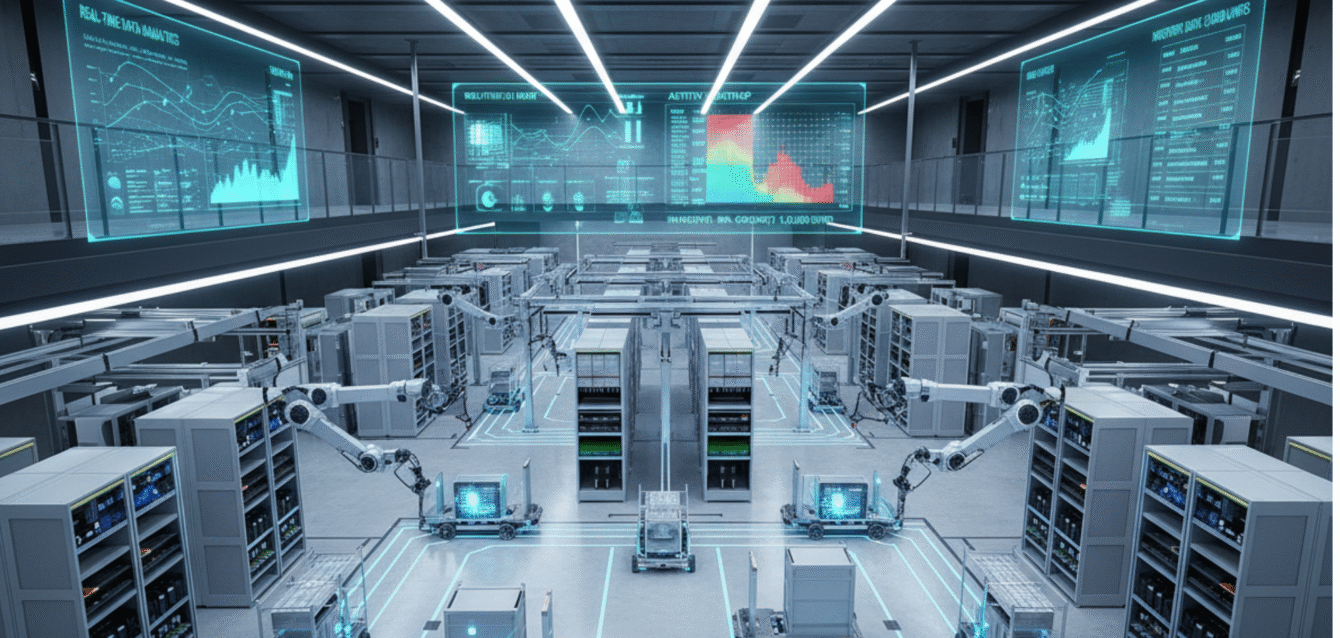

Smart space utilisation depends on more than one‑off audits—it needs continuous data on what’s happening in the facility: occupancy, travel time, material flow, staging patterns, equipment location and unused zones. Technologies such as IoT sensors, heat‑mapping, spatial analytics and digital twins enable this. For example, sensors can track where forklifts wait, where pallets accumulate, how often workstations idle, and how pathways are used. With this data, analytics can generate insights into bottlenecks, under‑used areas, frequent cross‑traffic and layout drift. In fact, one study highlights how smart space management captures real‑time usage and transforms reactive maintenance into proactive planning.

Once the data backbone is in place, the analytics layer delivers value: dashboards of utilisation rates per zone, comparisons of expected vs actual flow, visualisations of dead space, and predictive recommendations for layout change. With this insight, industrial planners move from intuition‑based decisions to evidence‑based infrastructure planning. Space is no longer static—it is measured, monitored and optimised.

Aligning Storage, Movement and People for Optimal Flow

Space utilisation is only part of the challenge—how you align storage, material movement, human traffic and equipment matters equally. A layout may have plenty of racks, but if high‑turnover items are stored far from dispatch, travel time increases. If aisles are overly wide, space is wasted and picking efficiency drops. Smart infrastructure planning connects storage strategy (fast‑ vs slow‑moving stock), movement patterns (forklift or AGV paths, human walking distances), and people interactions (handoffs, waiting zones, congestion points). By overlaying usage data with layout geometry, planners can reposition racks, adjust aisle widths, relocate staging areas and define one‑way flows to reduce movement, minimise conflict and increase throughput.

This alignment also supports dynamic space: as SKU mix shifts, new lines are introduced or demand changes, the infrastructure adapts rather than remains fixed. For example, space originally designed for slow‑moving inventory can be repurposed into a buffer or staging zone for fast‑moving items, and travel paths can be adjusted based on actual movement heat‑maps, rather than default assumptions. The result is infrastructure that flexes with demand, not fights it.

Technology‑Enabled Capabilities That Drive Space Efficiency

To function at scale, smart space utilisation leverages a set of enabling capabilities: real‑time occupancy tracking, movement heat‑maps, asset location, virtual layout models, dynamic slotting, utilization dashboards and predictive alerts. These tools translate raw data into actionable insights and operational changes. Key capabilities include:

Real‑time occupancy and zone utilisation dashboards

Heat‑maps showing travel distances, crane or forklift wait times and worker traffic

Asset‑location visibility identifying under‑used or redundant zones

Simulation tools for “what‑if” layout changes or new line additions

Automated alerts when utilization dips below threshold or congestion exceeds defined limits

These capabilities allow infrastructure teams to monitor actual space usage, test layout modifications virtually, and implement changes that deliver measurable gains. When infrastructure is smart, it becomes a living system—not a fixed floor plan.

Quick Wins to Boost Space Utilisation in 30‑60 Days

Smart space utilisation isn’t a year‑long waiting game—it can deliver rapid results when implemented correctly. Within one to two months, facilities typically see gains like liberated aisle space, reduced travel distances, clearer staging areas, reclaimed zones for high‑turnover stock, and better alignment of labour with flow. These early wins often come from simple actions: adjusting slotting of fastest‑moving SKUs, narrowing or repurposing under‑used aisles, redefining buffer zones, implementing traffic segregation for vehicles and pedestrians, and refining scheduling to level‑load labour and equipment. Once visible improvements show up, adoption accelerates and infrastructure becomes a lever for performance rather than a cost sink.

These early changes also build stakeholder confidence—when operations see improved throughput or reduced travel time, infrastructure planning earns a strategic seat. Momentum then carries into deeper initiatives: digital twin modelling, AI‑driven slotting, phased layout redesign and expansion planning based on real‑time flows.

Supporting Sustainability and Capital Efficiency with Better Space Use

Better space utilisation isn’t just operational—it aligns with sustainability, cost control and capital efficiency. When facilities use space more effectively, they avoid unnecessary expansion, reduce heating, cooling and lighting loads for unused zones, and lower real‑estate cost per square metre. Smart space planning therefore becomes a contributor to green operations, aligning with both operational excellence and environmental goals. For example, research into smart industrial spaces shows energy‑efficient planning driven by digital sensors and IoT platforms results in lower resource consumption and optimised deployment of space.

From a capital perspective, efficient space means fewer square metres needed for the same or higher throughput, which translates into lower capital expenditure, reduced lease or build‑costs, and greater return on facility assets. Infrastructure becomes an enabler of growth—not a barrier. When space serves performance rather than simply containing it, the business operates leaner, scales faster and invests smarter.

Embedding Smart Space Utilisation into Infrastructure Planning Culture

The final dimension of smart space utilisation is cultural: it’s not enough to install sensors and visualise data—organisations must embed an ongoing process of monitoring, review, adaptation and improvement. Infrastructure teams should establish governance around space‑metrics (utilisation thresholds, travel time targets, congestion limits), review flows monthly, redefine roles for monitoring, and tie space performance to business outcomes. Over time, this becomes part of the organisational rhythm: layout changes, slotting updates, travel path redesigns, and capacity planning are done not annually but continuously. With smart infrastructure planning culture in place, the facility becomes a living system, adaptable to demand shifts, resilient to disruptions and aligned with performance goals rather than just capacity targets.

When planning, operations and finance speak the same language about space, and real‑time usage data becomes a key performance indicator, the business moves from reacting to space issues to engineering outcomes. Smart space utilisation becomes foundational to industrial infrastructure strategy.

The Takeaway

Smart space utilisation is no longer optional—it’s fundamental to modern industrial infrastructure planning. When layout, movement, occupancy and asset positioning are tracked, analysed and optimised continuously, facilities achieve higher throughput, lower cost, faster change‑over, and sustainable growth. Space isn’t just what you have—it’s what you use, manage and optimise.