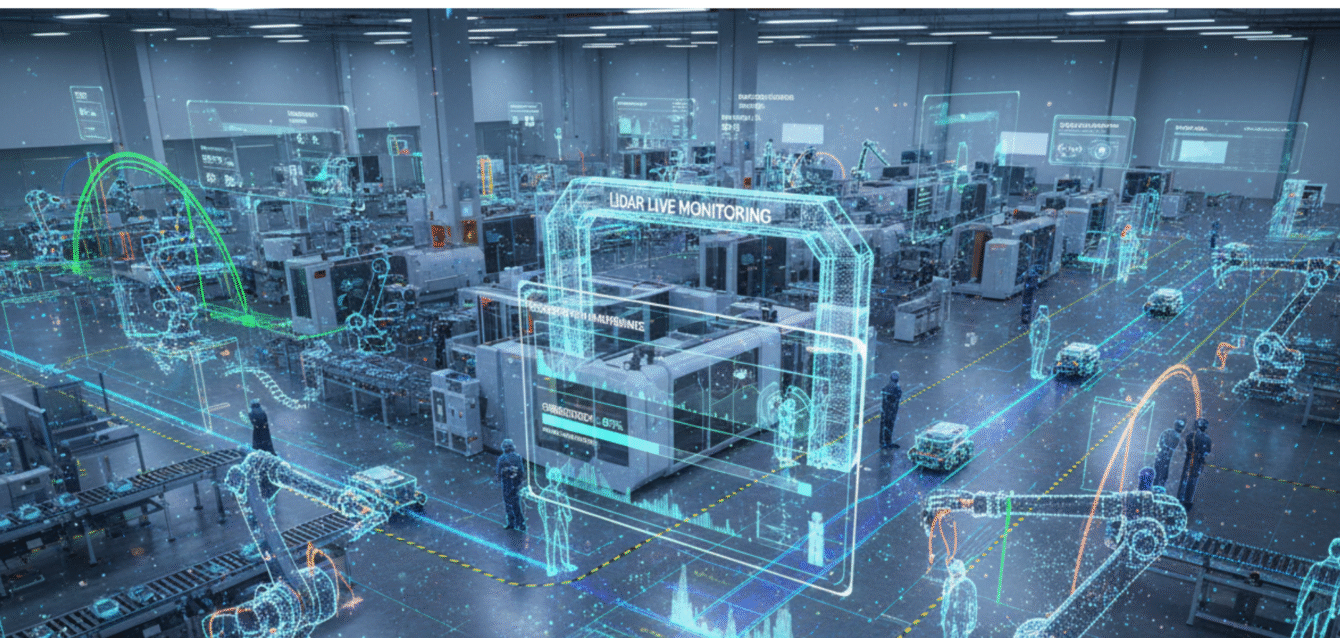

In the era of industrial transformation known as Fourth Industrial Revolution (Industry 4.0), physical assets, production flows and facility spaces are becoming digitised in ways that were previously unimaginable. What once began as discrete mapping efforts—scanning building shells, warehouse layouts or production…

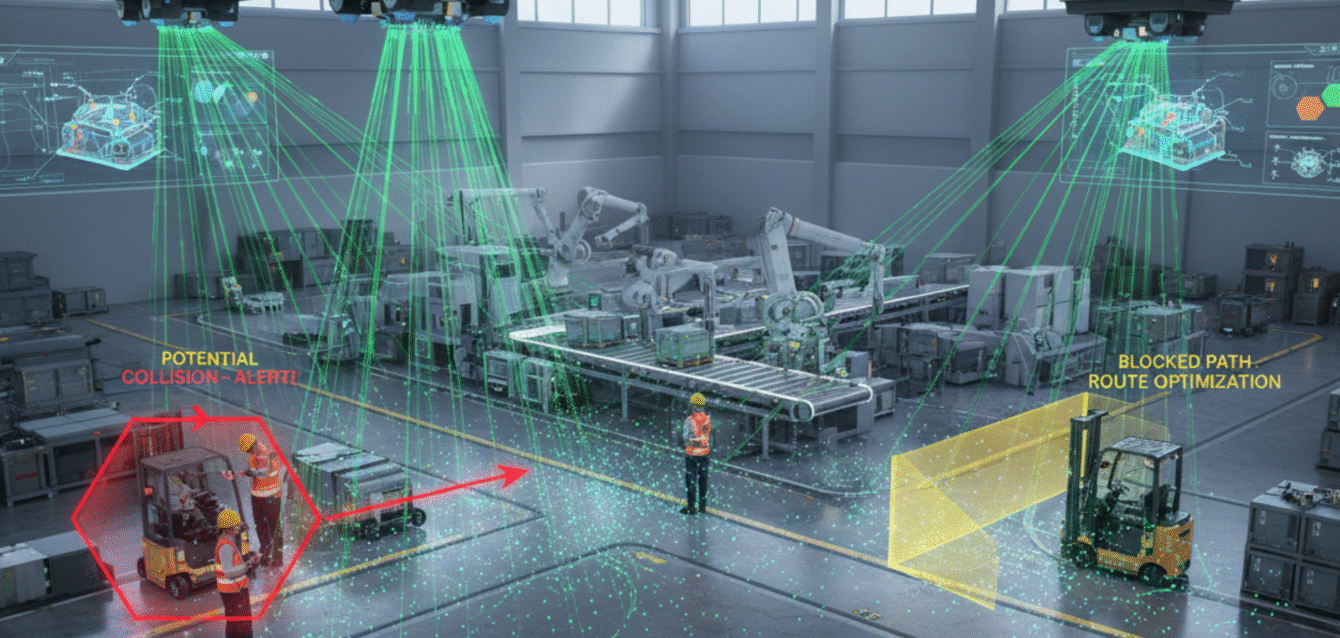

How LiDAR Improves Workplace Safety and Efficiency

In industrial environments—whether factories, warehouses, production floors or logistics hubs—the interplay between safety and efficiency is constant. Workers, machines, vehicles and materials all share the same space and rhythm. Even small blind spots, slow handoffs or hidden bottlenecks can lead to…

Predictive Analytics for Smarter Inventory Forecasting

In modern supply chains, the old adage holds: too much inventory ties up precious capital, while too little inventory risks lost sales, unhappy customers and production disruptions. Traditional forecasting methods—based on averages, fixed reorder points or instinct—no longer suffice in environments…

Reimagining Industrial Spaces with LiDAR-Based Spatial Intelligence

In expansive industrial settings—whether manufacturing halls, warehouses, logistics yards or multi‑level production zones—space is both a resource and a constraint. When layout, movement paths, storage zones, equipment placement and safety clearances are all managed with static drawings and manual measurements, inefficiencies…

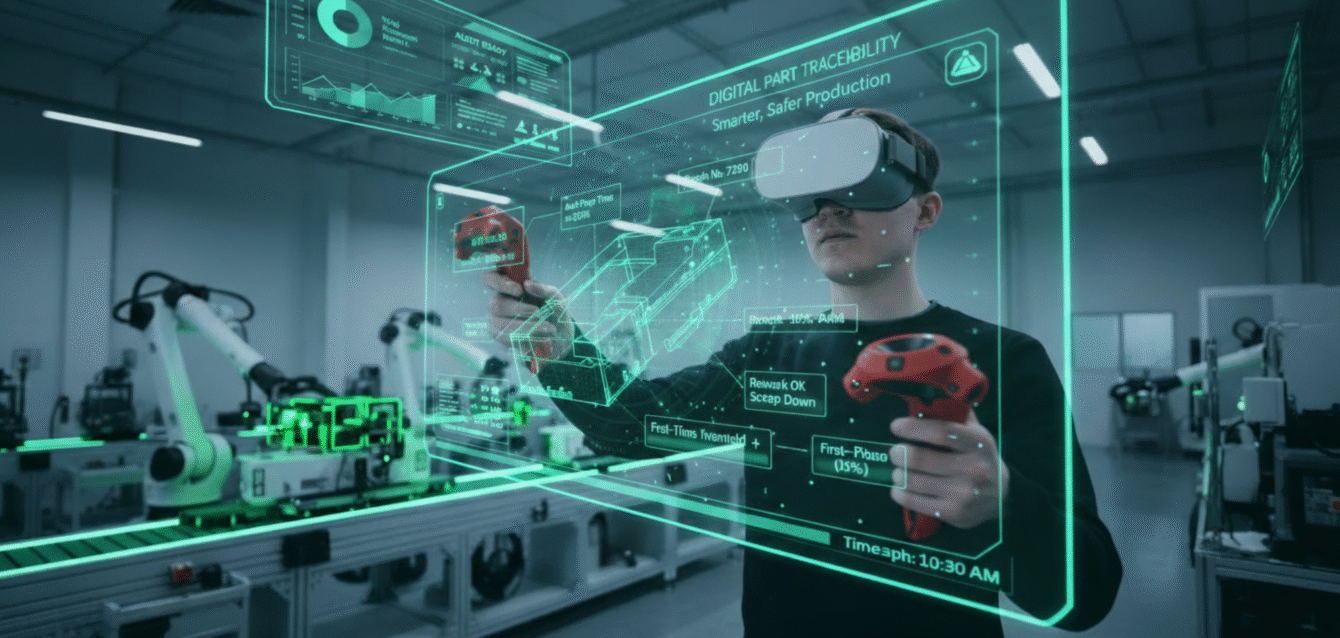

Why Digital Part Traceability Is the Key to Smarter, Safer Production

Manufacturing today faces rising expectations—faster delivery, tighter compliance, zero defects. But without the ability to track every part, process, and event, it’s easy for problems to slip through the cracks. That’s why digital part traceability has become a critical pillar of…

The Role of AI and IoT in Achieving Complete Traceability Across Supply Chains

In today’s global manufacturing and logistics environment, parts move through dozens of processes—raw materials to suppliers, shipments across continents, production lines, warehouses, carriers, and final delivery. The sheer complexity creates blind spots: delays that don’t get flagged, parts that stray off…

Reducing Downtime and Defects with Smart Part Tracking Solutions

Downtime and defects are two of the most stubborn challenges in manufacturing. While one brings production to a halt, the other chips away at quality, customer trust, and profitability. Most teams understand the consequences—but fewer have real-time tools that can prevent…

How Part Traceability Ensures Quality and Compliance in Modern Manufacturing

In the world of modern manufacturing, small mistakes can create big problems—whether it’s a single faulty component slipping through or a recall spiraling into thousands of wasted units. That’s why more factories are turning to digital part traceability systems that track…