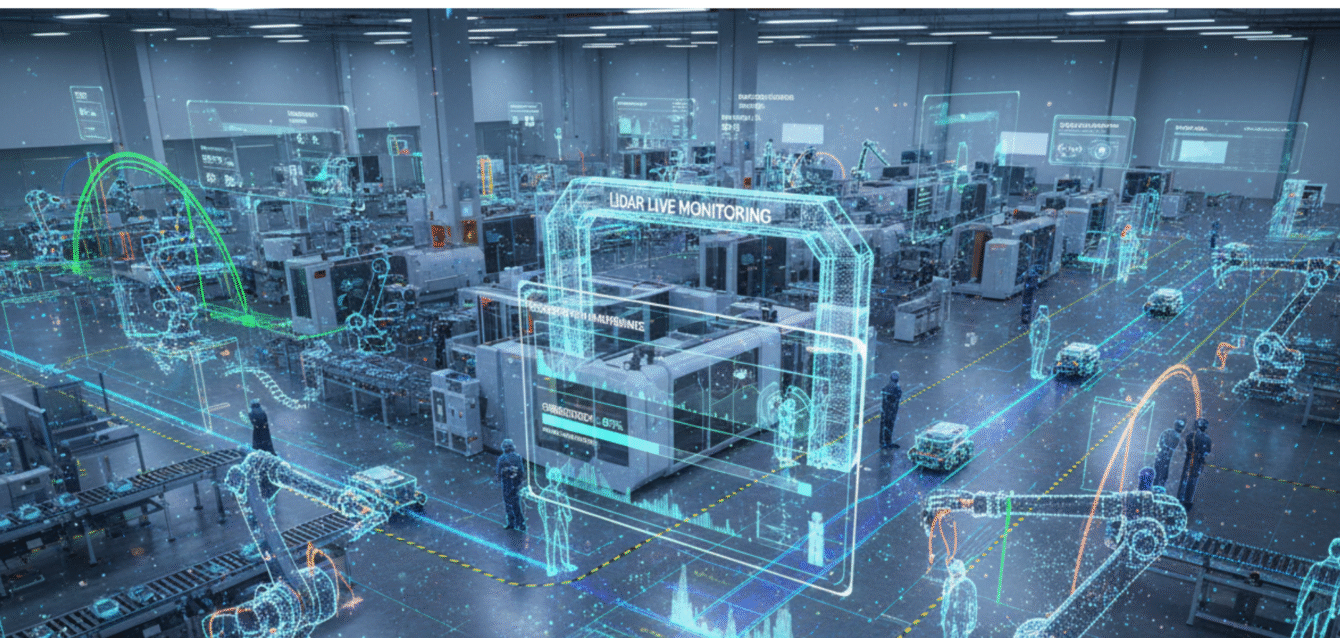

In the era of industrial transformation known as Fourth Industrial Revolution (Industry 4.0), physical assets, production flows and facility spaces are becoming digitised in ways that were previously unimaginable. What once began as discrete mapping efforts—scanning building shells, warehouse layouts or production…

Reducing Costs and Human Errors with Real-Time Inventory Visibility

In many businesses managing physical stock—whether finished goods, raw materials, or parts—the difference between profitability and loss often lies hidden in the inventory system. Manual counts, spreadsheets, disconnected databases, and delay‑laden reconciliations don’t just slow operations—they introduce human errors, mis‑matched records,…

Real-Time Supply Chain Visibility: Seeing Issues Before Customers Do

In an era where every hour of delay, every mismatch in documentation, and every unseen hand‑off in transport can ripple into lost revenue or damaged reputation, live tracking systems are no longer optional—they’re integral. Traditional supply chains often operate with blind…

The Role of AI and IoT in Achieving Complete Traceability Across Supply Chains

In today’s global manufacturing and logistics environment, parts move through dozens of processes—raw materials to suppliers, shipments across continents, production lines, warehouses, carriers, and final delivery. The sheer complexity creates blind spots: delays that don’t get flagged, parts that stray off…