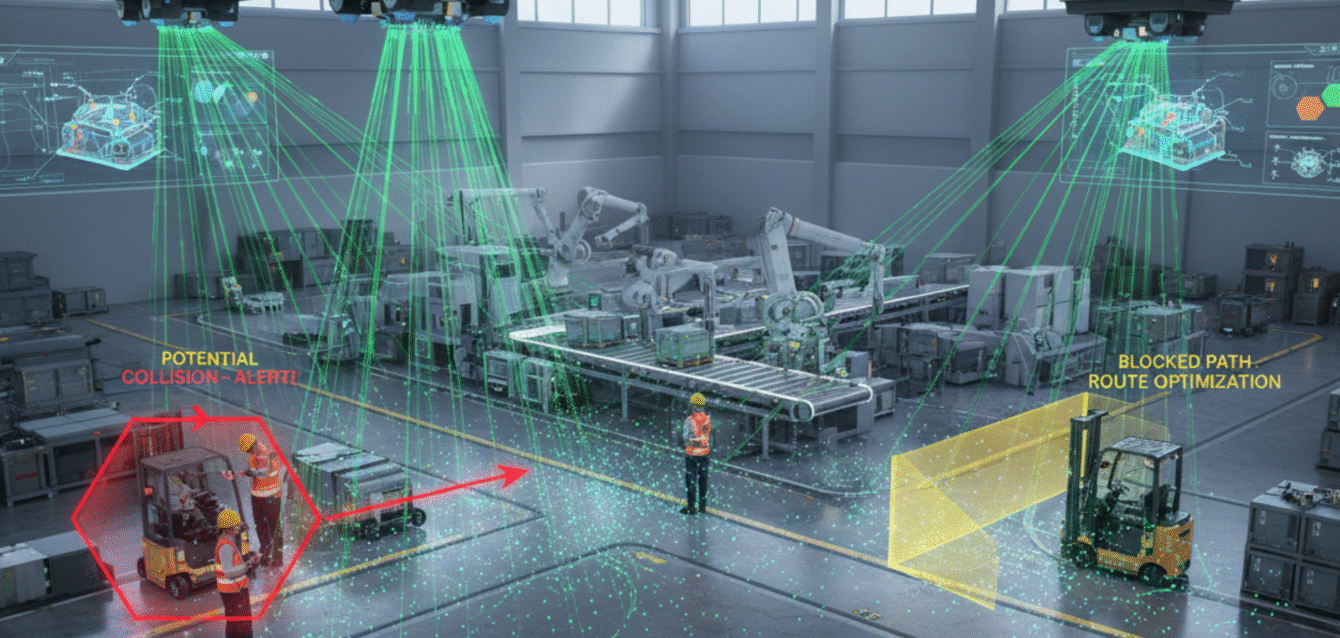

In industrial environments—whether factories, warehouses, production floors or logistics hubs—the interplay between safety and efficiency is constant. Workers, machines, vehicles and materials all share the same space and rhythm. Even small blind spots, slow handoffs or hidden bottlenecks can lead to…

Automation in Warehousing: The Key to Seamless Inventory Flow

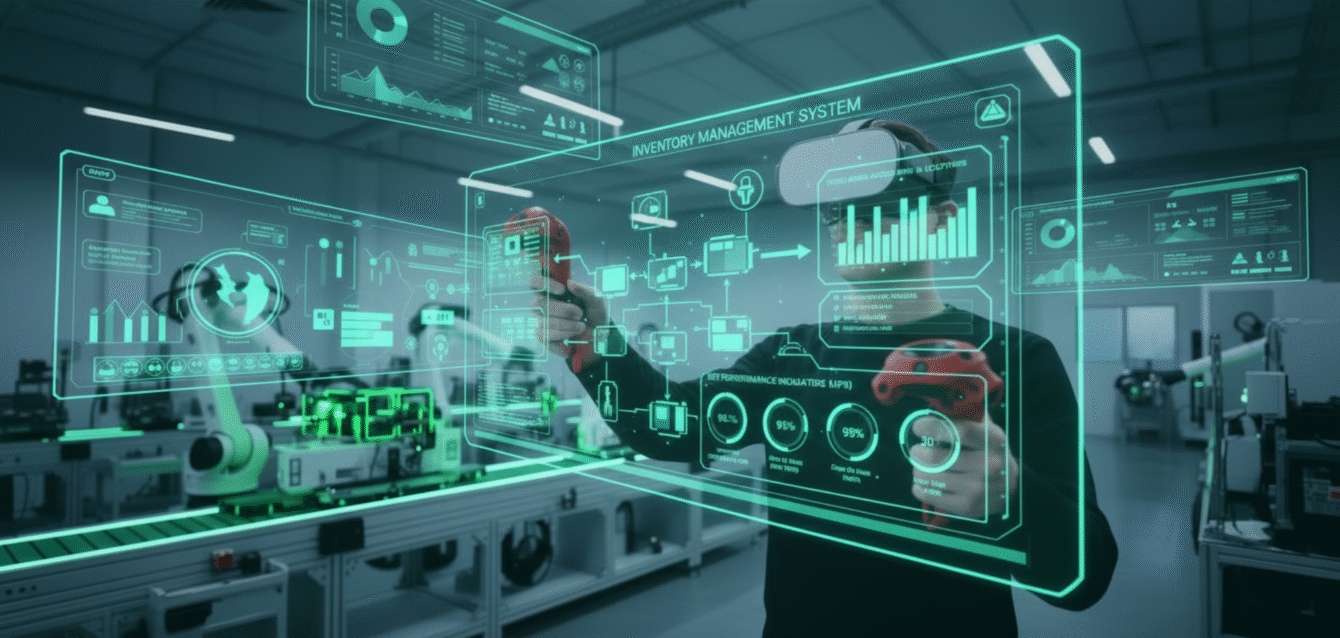

In today’s warehousing environment, where customer expectations accelerate and inventory volumes grow in complexity, manual processes simply can’t keep pace. Workflows that rely on manual picking lists, paper check‑ins, long walking routes, and fragmented systems create bottlenecks, errors, delays and hidden…

How Smart Inventory Management Minimizes Losses and Maximizes Efficiency

Inventory is the lifeline of any business that deals with physical products. Whether in manufacturing, retail, or distribution, managing stock correctly can make or break operational efficiency. Poor inventory practices not only lead to losses due to miscounts, theft, and expiry…

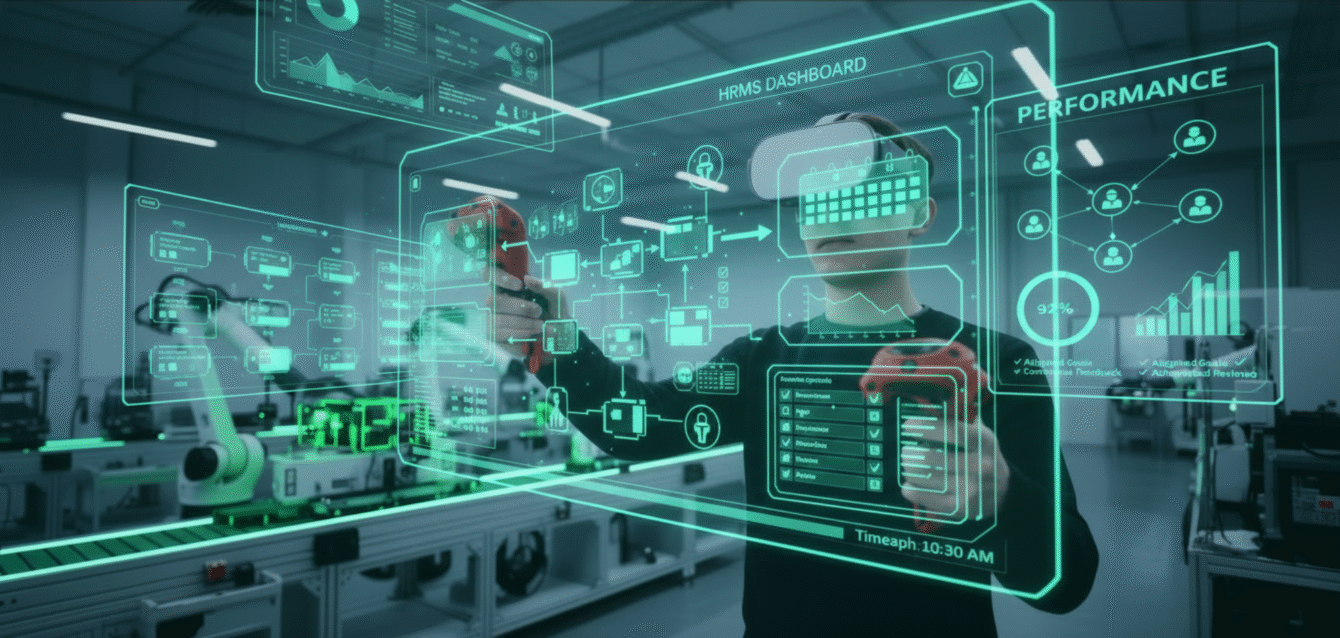

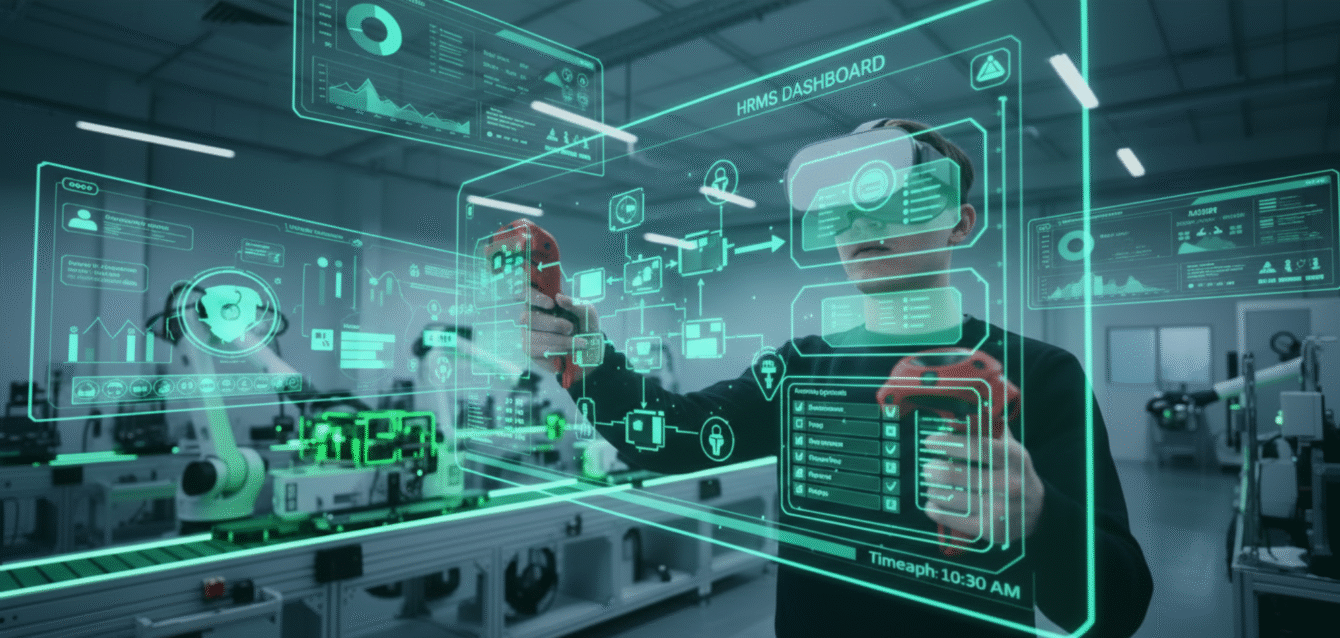

Streamlining Recruitment, Payroll, and Performance with Intelligent HR Systems

Recruitment, payroll, and performance management are at the heart of every organization’s human resource operations. Yet, in many workplaces, these essential functions operate in isolation, relying on disjointed systems and manual interventions that cause delays, errors, and frustration. Hiring a new…

Reducing Costs and Human Errors with Real-Time Inventory Visibility

In many businesses managing physical stock—whether finished goods, raw materials, or parts—the difference between profitability and loss often lies hidden in the inventory system. Manual counts, spreadsheets, disconnected databases, and delay‑laden reconciliations don’t just slow operations—they introduce human errors, mis‑matched records,…

The Digital HR Revolution: Moving Beyond Spreadsheets and Manual Processes

Custom development of machine learning models tailored to your specific business needs, leveraging algorithms and techniques such as regression, classification, clustering, and deep learning.

From Chaos to Clarity: Managing the Asset Lifecycle with ATLAS Pro

In many factories and heavy equipment operations, assets such as tools, machines, jigs and instruments can quietly become sources of chaos. They’re purchased, moved, repaired, loaned out, lost, mis‑tagged, or forgotten. When assets aren’t tracked properly, you get unexpected downtime, lost…

Reducing Downtime and Defects with Smart Part Tracking Solutions

Downtime and defects are two of the most stubborn challenges in manufacturing. While one brings production to a halt, the other chips away at quality, customer trust, and profitability. Most teams understand the consequences—but fewer have real-time tools that can prevent…

How Part Traceability Ensures Quality and Compliance in Modern Manufacturing

In the world of modern manufacturing, small mistakes can create big problems—whether it’s a single faulty component slipping through or a recall spiraling into thousands of wasted units. That’s why more factories are turning to digital part traceability systems that track…