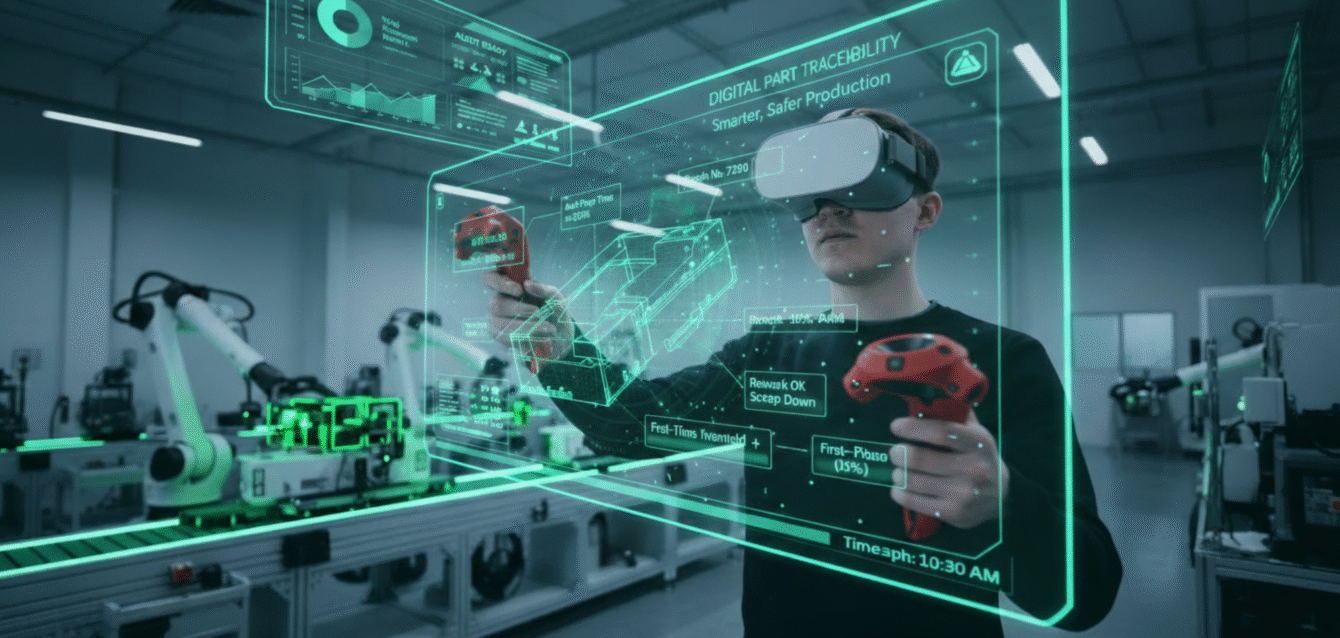

Manufacturing today faces rising expectations—faster delivery, tighter compliance, zero defects. But without the ability to track every part, process, and event, it’s easy for problems to slip through the cracks. That’s why digital part traceability has become a critical pillar of smarter, safer production.

The Risks of Running Without Digital Traceability

In plants that rely on manual tracking or scattered systems, things get missed. When something goes wrong, it’s hard to know what was affected—or even where to start looking.

Without digital traceability, teams face:

- Blind spots in production history

- Delays in diagnosing quality issues

- Broad, costly recalls due to lack of specificity

- Compliance failures and audit anxiety

These risks not only slow you down—they create long-term vulnerabilities.

Faster Product Launches and Changeovers

Every time a new product is introduced or a change is made, mistakes can happen—wrong versions, misplaced parts, missed steps. Digital traceability ensures everyone is aligned from day one.

It helps by:

- Guiding parts to the right station based on version or BOM

- Ensuring correct materials and processes for each variant

- Recording which product versions ran on which line, and when

- Preventing outdated or unapproved materials from being used

This speeds up rollouts and reduces costly misbuilds.

Stronger Safety and Brand Protection

In safety-critical industries, even one bad part can cause harm. When incidents occur, being able to trace every detail instantly is crucial for customer safety and brand credibility.

Digital traceability supports safety by:

- Logging every process step and inspection result

- Proving compliance with industry-specific standards

- Making it easy to isolate issues before they spread

- Showing exactly which customers received affected parts

It’s about responding quickly and confidently—without panic or guesswork.

Easy Start, Fast Adoption

The best systems don’t require massive infrastructure or months of training. Digital traceability tools today are built to be intuitive, fast to deploy, and easy to scale.

What makes modern systems easy to adopt:

- User-friendly screens and dashboards

- Mobile or tablet support on the shop floor

- Role-based views for operators, QA, supervisors

- Quick training cycles—teams up and running in days, not months

When systems work for people—not against them—adoption happens naturally.

Beyond Quality: Supporting Planning and Purchasing

Traceability data isn’t just useful for quality—it’s gold for planning, purchasing, and logistics teams too. It creates a unified view of what’s happening in real time.

Examples of broader impact:

- Identifying reliable vs. problematic suppliers using trace data

- Improving demand forecasts based on actual consumption

- Reducing inventory waste by knowing exact part usage

- Supporting better negotiation with data-backed performance history

Traceability creates visibility across the business—not just in the plant.

Proving the Value with Real Metrics

When it comes to tech adoption, ROI matters. Digital traceability shows its value early—and keeps delivering over time.

Proof points to track include:

- Audit prep time reduced by 50% or more

- Recalls limited to <10% of total output

- Rework and scrap trending downward

- First-pass yield improvements over the first 3 months

- Better production planning accuracy

These are results that leadership sees—and teams feel—on the ground.

The Takeaway

Digital part traceability isn’t just a tool—it’s a transformation. It gives your team the data, visibility, and control they need to work smarter, safer, and faster. From launch to inspection, from supplier to shop floor, it connects every part of your process with clarity and precision.

In an environment where speed and safety go hand in hand, this is the system that lets you do both—without compromise.